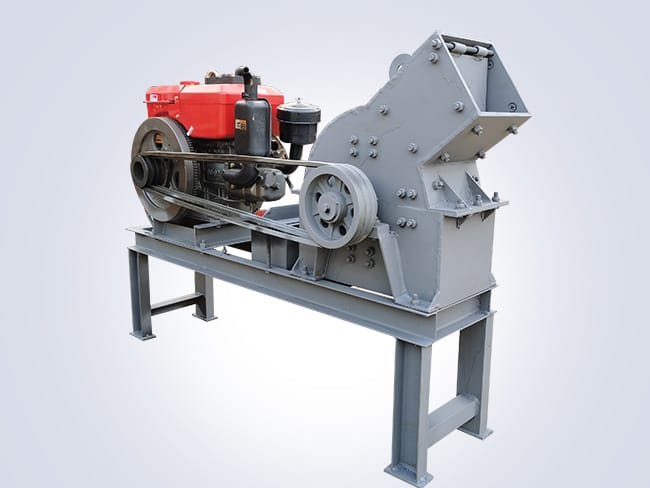

As one of the core pieces of equipment in the industrial crushing field, the hammer crusher is widely used in multiple industries such as mining, building materials, chemicals. And metallurgy, thanks to its efficient and flexible characteristics. Its working principle involves impact crushing of materials through high-speed rotating hammers, making it suitable for coarse, medium. And fine crushing operations of medium- to low-hardness materials.

Hammer Crusher: A Competent Equipment for Efficient Crushing Across Multiple Fields

In the mining sector, hammer crushers are commonly employed for primary crushing of ores such as limestone and coal gangue. Their simple structure and ease of maintenance significantly enhance production efficiency. In the building materials industry, these crushers can break down construction waste. And concrete blocks into recycled aggregates, facilitating resource recycling. In the chemical and metallurgical industries. The equipment is used to process raw materials such as coal, coke, and salt, ensuring uniform particle size to meet subsequent process requirements.

Compared to traditional crushing equipment, hammer crushers offer advantages such as a large crushing ratio, low energy consumption, and adjustable product particle size. In recent years, with technological advancements, new-generation hammer crushers have further improved their wear resistance. And processing capacity by optimizing hammer materials and enhancing grate bar structures, becoming key equipment in sand and gravel aggregate production lines and cement production lines. Looking ahead, with the deepening of concepts such as green mining and circular economy. These crushers will continue to innovate in terms of energy conservation, emission reduction, and intelligent control, providing more efficient solutions for industrial production.