In industries such as mining and building materials production, the hammer crusher is an indispensable key piece of equipment. With its unique crushing principle and high-efficiency performance, it serves as a capable assistant for material crushing and processing.

Hammer Crusher: A “Crushing Powerhouse” in the Mining and Building Materials Sectors

The hammer crusher primarily relies on high-speed rotating hammers to impact materials, causing them to repeatedly collide. And break between the rotor disc and the impact plate until the desired particle size is achieved. This crushing method combines impact and grinding actions, featuring a large crushing ratio. It can crush large chunks of material into smaller sizes in one go, significantly enhancing production efficiency.

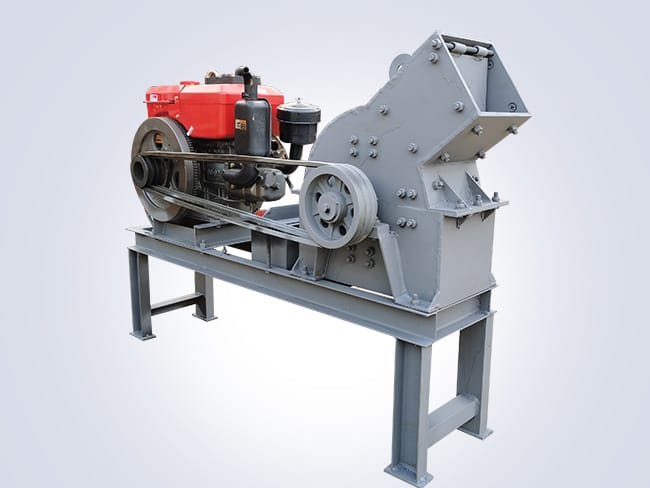

Its structure is relatively simple, mainly comprising components such as the casing, rotor, hammers, and impact plate. This simplicity not only facilitates easy installation and maintenance but also effectively reduces equipment failure rates, minimizes downtime, and ensures production continuity. Moreover, the hammer crusher has a wide range of applications, capable of crushing various medium-hard and brittle materials, such as limestone, coal, and shale.

As technology continues to advance, the equipment is constantly being optimized and upgraded. New models have demonstrated significant improvements in energy efficiency and wear resistance, further reducing production costs and providing strong support for the sustainable development of enterprises. They will continue to play a crucial role in future industrial production.